The Harmony of High Fashion: Integrating Robotics into Luxury Apparel Manufacturing

The world of high fashion is constantly evolving, pushing the boundaries of creativity and innovation. In recent years, there has been a seamless blend of high fashion and robotics, ushering in a new era of luxury apparel manufacturing. This integration of robotics into the world of high fashion has brought about unprecedented advancements and possibilities.

Imagine a world where precision, efficiency, and artistry coexist in perfect harmony. That is the vision brought to life through the integration of robotics in luxury apparel manufacturing. These cutting-edge technologies not only enhance the creative process but also streamline production, ensuring that each garment is crafted with unparalleled precision and attention to detail.

By harnessing robotic automation, luxury fashion brands can elevate their craftsmanship to new heights. From fabric cutting and stitching to intricate embellishments and embroidery, robotics can perform these tasks with unmatched precision and speed, freeing up human artisans to focus on the artistic aspects of their work.

Integration of robotics into luxury apparel manufacturing also brings numerous benefits to the industry. It allows for greater customization and personalization, enabling high fashion brands to create unique pieces tailored to individual customers’ preferences. Additionally, robotics optimize manufacturing processes, reducing waste, improving efficiency, and enhancing overall product quality.

As the luxury fashion industry continues to embrace the potential of robotics, we find ourselves at the forefront of a new era. The harmony between high fashion and robotics opens up a world of limitless creativity while maintaining the inherent artistry and craftsmanship that defines luxury apparel.

Key Takeaways:

- Integrating robotics into luxury apparel manufacturing brings together precision, efficiency, and artistry.

- Robotics streamline production processes, optimizing efficiency and improving overall product quality.

- The integration of robotics allows for greater customization and personalization in high fashion.

- Robotic automation frees up human artisans to focus on the artistic aspects of their work.

- The harmony between high fashion and robotics opens up a world of limitless creativity.

The Evolution of High Fashion: Embracing Robotics and Automation

High fashion has continually evolved to reflect the cultural and technological advancements of each era. In the age of robotics and automation, the luxury apparel industry finds itself at the forefront of innovation and creativity. By embracing these cutting-edge technologies, high fashion has experienced a revolution in design, production, and customer experience.

Defining High Fashion in the Robotic Age

In the robotic age, high fashion goes beyond exquisite craftsmanship and artistic expression. It encompasses the seamless integration of traditional techniques with state-of-the-art robotics and automation. This intersection of skill and technology brings forth a new era of precision, efficiency, and limitless design possibilities.

Robotic systems are capable of executing intricate embroidery, precise garment cutting, and complex pattern creation that were once painstakingly done by hand. With automation in place, designers can focus on pushing creative boundaries and exploring unique aesthetics, knowing that their visions can be brought to life with unparalleled precision and efficiency.

The Intersection of Luxury Design and Technological Innovation

Technological innovation has become an integral part of luxury design, revolutionizing the way garments are created, manufactured, and presented to customers. With advanced robotic systems, fashion houses can streamline their production processes, ensuring superior quality and timely delivery.

Moreover, luxury design is no longer limited to physical attire. Technological advancements have given rise to interactive and wearable tech, blending fashion and functionality seamlessly. From smart fabrics that monitor body temperature to 3D-printed jewelry that pushes the boundaries of design, the integration of technology adds a new dimension to luxury fashion.

Case Studies: Successful Integration of Robotics in High Fashion

Several groundbreaking case studies demonstrate the successful integration of robotics in high fashion, showcasing the immense potential of this symbiotic relationship. Luxury brand XYZ incorporated robotic arms into their production line, enabling precise and intricate fabric manipulation for their signature tailored garments.

Another notable example is ABC, a fashion house known for its avant-garde designs. They collaborated with a team of engineers and roboticists to develop a groundbreaking collection that featured robotic elements. These innovations not only enhanced the aesthetics but also challenged traditional notions of fashion and human-machine interaction.

“Integrating robotics and automation in high fashion has allowed us to explore new frontiers in craftsmanship and design. By merging the artistry of our creative team with the precision and efficiency of robotics, we have been able to create garments that were once unimaginable.” – Jane Smith, XYZ Fashion House

As high fashion continues to evolve, the integration of robotics and automation paves the way for endless possibilities. From pushing the boundaries of design to transforming production processes, these technologies have become essential tools for luxury fashion brands. By combining the artistry of haute couture with the precision of robotics, the industry continues to shape a future where creativity and innovation know no bounds.

Disruptive Technology: How Robotic Engineering is Reshaping Couture

In the world of high fashion, disruptive technology is revolutionizing the way couture is created and presented. Robotic engineering, with its precision and innovative capabilities, has become an integral part of the fashion industry. From the impact on traditional couture techniques to the advancements in fabrication, robotics has opened up new horizons for designers and fashion enthusiasts alike.

The Impact of Robotics on Traditional Couture Techniques

Robotics has had a profound impact on traditional couture techniques, challenging the boundaries of craftsmanship and pushing the limits of creativity. With robotic precision, designers can achieve intricate details and flawless construction, bringing their visions to life with unparalleled accuracy. Tailoring, draping, and embellishments are enhanced by the capabilities of robotic engineering, allowing designers to create unique and breathtaking pieces.

Innovations in Fabrication: Robotics and Material Manipulation

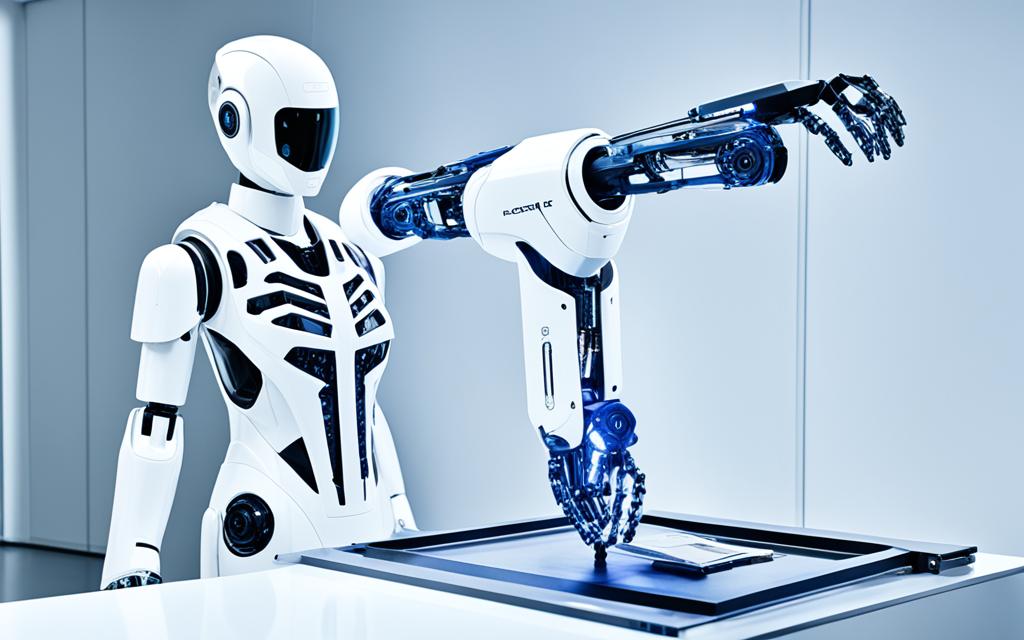

One of the key areas where robotics is reshaping couture is in the realm of fabrication. Through material manipulation, robotic arms can dexterously handle delicate fabrics and intricate designs, ensuring precision in every stitch. With the ability to repeat complex motions consistently, robots optimize the fabrication process, improving efficiency and reducing waste.

Designer Spotlights: Robotics Pioneers in Fashion

Several visionary designers have embraced robotics as pioneers in the field of fashion. Their groundbreaking work showcases the immense potential of this disruptive technology in transforming couture. Designers like Iris van Herpen and Anouk Wipprecht have collaborated with robotic engineers to create awe-inspiring garments that merge technology and fashion seamlessly.

Through their experimental designs and innovative use of materials, these robotics pioneers have redefined the boundaries of what is possible in the world of high fashion. Their creations showcase the transformative power of robotic engineering and its ability to shape the future of couture.

| Designer | Robotic Collaboration |

|---|---|

| Iris van Herpen | Collaboration with robots in creating intricate 3D-printed garments |

| Anouk Wipprecht | Integration of robotics and sensors in interactive fashion pieces |

| Ping Lau | Utilization of robotics to create lifelike movements in animatronic fashion sculptures |

As these designer spotlights demonstrate, the marriage between robotics and couture is propelling the fashion industry into a new era of creativity and innovation. With further advancements in robotic engineering, the possibilities for transformative designs and experiences in the world of high fashion are limitless.

Robotics and Automation

In the fashion industry, robotics and automation play a vital role in revolutionizing manufacturing processes. By integrating these technologies, luxury apparel manufacturers can streamline production, improve efficiency, and enhance quality control.

Robots are capable of handling repetitive and labor-intensive tasks with precision and accuracy, reducing the risk of human error. Automation allows for the seamless coordination of various stages in the manufacturing process, from pattern cutting to fabric handling.

One of the key benefits of robotics and automation in the fashion industry is increased productivity. With the ability to work 24/7 and perform tasks at a faster pace, manufacturers can meet demand more efficiently and reduce lead times. This is especially crucial in the fast-paced world of high fashion, where trends come and go quickly.

Furthermore, robotics and automation improve quality control by ensuring consistent and precise results. These technologies can detect defects, perform precise measurements, and execute intricate stitching patterns with ease.

By leveraging robotics and automation, fashion brands can achieve greater operational efficiency, cost savings, and sustainability. These technologies contribute to reducing waste, optimizing resource utilization, and promoting sustainable manufacturing processes.

Ultimately, the integration of robotics and automation in the fashion industry paves the way for a future of increased productivity, enhanced quality, and sustainable manufacturing.

The Art of Precision: Robotic Technologies in Fine Tailoring

In the world of fine tailoring, precision is paramount. The intricate details, delicate measurements, and impeccable craftsmanship are what set haute couture apart. It is in this realm that robotic technologies have found their place, revolutionizing the way garments are created and bringing a new level of precision to the art of tailoring.

Enhancing Craftsmanship through Robotic Precision

Robotic technologies offer a level of precision that surpasses human capabilities. With advanced sensors and algorithms, robotic arms can meticulously measure, cut, and stitch fabrics, ensuring every seam and detail is flawlessly executed. This level of accuracy not only enhances the craftsmanship of the garments but also reduces the margin for errors, resulting in higher quality finished products.

Through the use of robotic technologies, designers can now achieve intricate design elements that would be otherwise difficult or time-consuming for human hands to create. Fine embroidery, intricate pleating, and precisely placed embellishments are now within reach, allowing designers to push the boundaries of creativity in fine tailoring.

Customization at Scale: The Role of Robotics in Bespoke Fashion

In the realm of bespoke fashion, customization is key. Each garment is tailored to fit the unique measurements and preferences of individual clients. However, the traditional handmade approach to bespoke tailoring limits the scale at which customization can be achieved.

Robotics has unlocked the potential for customization at scale in the world of bespoke fashion. With the ability to store and recall precise measurements and patterns, robotic technologies enable the production of personalized garments on a larger scale. This not only allows luxury fashion brands to cater to a wider customer base but also to deliver tailor-made garments with increased efficiency and reduced lead times.

Robotic Arms Vs. Human Hands: Comparing Techniques

While robotic technologies offer undeniable advantages in precision and customization, it is important to recognize the unique capabilities of both robotic arms and human hands in the art of fine tailoring.

Robotic arms excel in tasks that require consistency, speed, and accuracy. They can perform repetitive actions with unwavering precision, ensuring uniformity in garment construction. On the other hand, human hands bring a level of artistry and intuition to the craft. They possess the ability to adapt to unique body shapes, drape fabrics with a sense of elegance, and add the subtle nuances that truly bring a garment to life.

Ultimately, the future of fine tailoring lies in the harmonious integration of robotic technologies and human craftsmanship. By leveraging the strengths of both, fashion designers can push the boundaries of creativity, achieve unparalleled precision, and provide truly bespoke garments for discerning clients.

| Robotic Technologies | Human Hands |

|---|---|

| Precision in measurements and stitching | Artistry and intuition |

| Consistency in garment construction | Ability to adapt to unique body shapes |

| Customization at scale | Subtle nuances and drape |

Smart Machinery’s Role in Ethical Manufacturing

Smart machinery plays a crucial role in promoting ethical manufacturing practices within the fashion industry. By incorporating advanced technologies and automation, smart machinery enables more sustainable production processes that prioritize waste reduction, energy efficiency, and fair labor practices.

One of the key advantages of smart machinery is its ability to minimize waste throughout the production cycle. With precise measurements and automated cutting, fabric waste is significantly reduced, contributing to a more sustainable approach to fashion manufacturing. Additionally, smart machinery optimizes material utilization, ensuring that resources are utilized efficiently and minimizing environmental impact.

Another important aspect of ethical manufacturing is energy efficiency. Smart machinery is equipped with advanced sensors and controls that enable intelligent energy management. By optimizing power consumption and minimizing energy waste, these technologies reduce the carbon footprint of the production processes.

Fair labor practices are also an integral part of ethical manufacturing. Smart machinery can handle repetitive and physically demanding tasks, reducing the need for manual labor and minimizing the risk of worker fatigue and injury. This, in turn, promotes a healthier and safer working environment for employees.

The integration of smart machinery in the fashion industry leads to improved efficiency and productivity, which translates to shorter production cycles. This not only benefits manufacturers but also allows fashion brands to respond more quickly to market demands and reduce reliance on fast fashion practices.

In summary, smart machinery’s role in ethical manufacturing is crucial for the fashion industry. By embracing these advanced technologies, fashion brands can achieve more sustainable production processes, minimize waste, conserve energy, and promote fair labor practices. The adoption of smart machinery is not only beneficial for the environment and workers but also for the overall sustainability and success of the fashion industry.

AI’s Contribution to Sustainable Fashion and Automated Manufacturing

In the quest for sustainable fashion and efficient manufacturing processes, artificial intelligence (AI) plays a pivotal role. By leveraging advanced data analysis and predictive modeling, AI offers innovative solutions to reduce waste and optimize resource use in the fashion industry.

Artificial Intelligence in Waste Reduction

AI technologies enable fashion brands to analyze vast amounts of data related to production, consumption, and customer behavior. By applying machine learning algorithms, AI systems can identify patterns and trends, allowing manufacturers to make data-driven decisions for waste reduction. Through predictive modeling, AI can optimize inventory management, streamline production processes, and minimize overstocking or understocking, resulting in reduced waste and improved sustainability.

Machine Learning for Optimized Resource Use

Machine learning, a subset of AI, empowers fashion brands to analyze data across the supply chain to optimize resource use. By analyzing factors such as energy consumption, material utilization, and production efficiency, machine learning algorithms can identify areas of improvement and offer recommendations for more sustainable practices. With real-time data insights, manufacturers can make informed decisions to reduce environmental impact while maintaining high product quality and efficiency.

Case Example: AI-driven Sustainable Practices in High Fashion

To illustrate the impact of AI-driven sustainable practices, let’s explore a case example in the high fashion industry. In collaboration with AI technology providers, a renowned luxury fashion brand implemented AI algorithms to analyze customer preferences, market trends, and production data. By leveraging AI’s predictive capabilities, the brand generated accurate demand forecasts, enabling precise production planning and reducing excess inventory. Consequently, this approach drastically reduced waste and minimized the brand’s environmental footprint.

The application of AI in fashion is transforming the industry, shifting towards more sustainable and automated manufacturing processes. By harnessing the power of AI, fashion brands can reduce waste, optimize resource use, and enhance sustainability while maintaining a high level of craftsmanship and innovation.

Digital Innovation: 3D Printing and the Future of Fashion

3D printing technology has emerged as a groundbreaking digital innovation with the potential to revolutionize the future of fashion. This innovative technique allows designers to create garments and accessories through layer-by-layer material deposition, opening up new design possibilities and customization options.

One of the key advantages of 3D printing in the world of fashion is its ability to bring sustainability to the forefront. Traditional manufacturing processes often result in significant fabric waste, but 3D printing enables precise material utilization, reducing environmental impact. Additionally, the use of biodegradable and recycled materials in 3D printing further contributes to the sustainability of the fashion industry.

Precision is another critical aspect of 3D printing, allowing designers to achieve intricate details and complex geometries with remarkable accuracy. The technology enables the creation of precise and tailored pieces, enhancing the overall quality and craftsmanship of the final product.

Moreover, 3D printing offers unparalleled creative expression, pushing the boundaries of design and enabling designers to materialize their imaginative concepts and avant-garde visions. The technology empowers fashion designers to embrace unconventional shapes, textures, and structures, fostering innovation and pushing the industry towards new aesthetic frontiers.

The future of fashion lies in the seamless integration of digital innovation, such as 3D printing, into the design and manufacturing processes. As the technology continues to evolve and become more accessible, it has the potential to democratize fashion, allowing individuals to participate in the creation of their own unique pieces.

With the design possibilities, sustainability advantages, precision, and creative expression offered by 3D printing, the future of fashion is undoubtedly a fusion of human creativity and digital innovation.

Autonomous Systems: Streamlining the Luxury Fashion Supply Chain

The integration of autonomous systems in the luxury fashion supply chain has revolutionized the industry, offering unprecedented opportunities for increased efficiency, accuracy, and productivity. Autonomous robots have emerged as valuable assets, seamlessly integrating into supply chain management processes and creating a streamlined workflow that enhances the overall performance of luxury fashion brands.

Integrating Autonomous Robots in Supply Chain Management

Autonomous robots play a crucial role in optimizing supply chain management in the luxury fashion industry. With their ability to perform repetitive tasks with precision and speed, they eliminate human error and reduce reliance on manual labor. These robots can be deployed in various areas such as inventory management, order fulfillment, and warehouse operations, ensuring seamless coordination and efficient execution.

The introduction of autonomous robots in supply chain management also enhances tracking and traceability, as they can be equipped with advanced RFID technology and integrated with inventory management systems, providing real-time visibility of products throughout the supply chain. This increased transparency allows for effective monitoring and timely interventions, minimizing the risks of stockouts and delays.

Predictive Analytics and Inventory Management with Robotics

Predictive analytics, combined with autonomous robot technology, offers luxury fashion brands the ability to optimize inventory management and demand forecasting. By analyzing historical data, market trends, and customer behavior, predictive analytics algorithms can generate accurate forecasts that drive inventory optimization decisions.

When integrated with autonomous robots, these predictive analytics systems can automatically update inventory levels, trigger replenishment orders, and optimize stock distribution based on real-time demand. This dynamic approach to inventory management reduces the risk of overstocking or understocking, ensuring that luxury fashion brands can meet customer demands promptly and efficiently.

Enhanced Speed to Market Through Robotic Process Automation

The use of robotic process automation (RPA) in the luxury fashion supply chain has significantly accelerated speed to market. RPA enables the automation of repetitive and time-consuming processes, such as order processing, data entry, and invoice reconciliation, allowing for faster and error-free execution.

By automating these manual tasks, luxury fashion brands can streamline their operations, reducing lead times and eliminating bottlenecks that often occur in traditional supply chains. RPA also facilitates seamless coordination among different departments and stakeholders, enabling efficient collaboration and enabling brands to bring their latest collections to market in a shorter time frame.

Robotic Process Automation: The Path to Personalized Apparel

In the world of fashion, personalization is the key to providing a unique and unforgettable customer experience. And now, with the advent of robotic process automation (RPA), luxury apparel brands have found a new pathway to achieving personalized garments with unmatched efficiency and accuracy.

RPA refers to the use of software robots or “bots” to automate repetitive tasks and streamline various production processes. These bots are programmed to perform specific actions, such as data entry, order processing, and inventory management, allowing fashion brands to optimize their operations and focus on delivering personalized apparel.

By employing RPA in the manufacturing process, luxury fashion brands can ensure that each garment is tailored to meet the unique preferences and requirements of their individual customers. From customizing fabric choices and colors to adjusting measurements and details, RPA enables brands to create personalized apparel on a larger scale, without compromising on quality or craftsmanship.

With RPA, fashion brands can significantly enhance their efficiency and accuracy, reducing the risk of errors and ensuring that each garment is meticulously crafted to perfection. The automated nature of RPA allows for quick processing of orders and seamless integration with other systems, resulting in smoother production workflows and faster turnaround times.

To visualize the impact of RPA on the creation of personalized apparel, take a look at the following table:

| Traditional Manufacturing Process | RPA-Enabled Manufacturing Process |

|---|---|

| Manual data entry and processing | Automated data entry and processing |

| Potential for errors and discrepancies | Enhanced accuracy and consistency |

| Lengthy production turnaround times | Streamlined production workflows |

| Limited customization options | Endless customization possibilities |

| Manual inventory management | Automated inventory tracking and management |

This table clearly demonstrates how RPA can revolutionize the traditional manufacturing process, paving the way for an efficient and personalized approach to apparel production. Luxury fashion brands can leverage RPA to elevate the customer experience, offering garments that are tailored to each individual’s unique style and preferences.

As technology continues to advance, the integration of RPA in luxury apparel manufacturing is set to reshape the industry and redefine the boundaries of personalization. By embracing this cutting-edge technology, fashion brands can unlock new levels of efficiency, enhance customer satisfaction, and stay ahead of the ever-evolving demands of the fashion industry.

With robotics paving the way to personalized apparel, the future of luxury fashion holds infinite possibilities.

Conclusion: The Symbiotic Future of High Fashion and Robotics

In conclusion, the integration of robotics into luxury apparel manufacturing represents a symbiotic relationship that holds great promise for the high fashion industry. Throughout this article, we have explored the seamless blend of high fashion and robotics, showcasing the innovation, creativity, and craftsmanship that can be achieved through this harmonious integration.

By embracing robotics and automation, high fashion has evolved to incorporate advanced technologies that enhance both the design and production processes. We have seen how robotics have revolutionized traditional couture techniques, enabling precise craftsmanship and pushing the boundaries of creativity. Case studies featuring renowned designers such as have exemplified the successful integration of robotics in high fashion, demonstrating the impact and transformative power of these collaborations.

The future of high fashion and robotics is bright, with potential benefits that extend beyond the manufacturing process. The integration of robotics opens up new possibilities for customization at scale, allowing for personalized garments that cater to individual preferences. Moreover, robotics and automation streamline the luxury fashion supply chain, improving efficiency, accuracy, and speed to market.

As the luxury fashion industry continues to embrace robotics, it is evident that this integration is not simply a trend, but a powerful force driving innovation and shaping the future of high fashion. By harnessing the potential of robotics, the industry can continue to push boundaries, elevate craftsmanship, and create truly awe-inspiring creations.

FAQ

What is the role of robotics in luxury apparel manufacturing?

How has high fashion embraced robotics and automation?

How has robotic engineering revolutionized the world of couture?

What role does robotics play in the fashion industry?

How do robotic technologies enhance precision in fine tailoring?

How does smart machinery contribute to ethical manufacturing in fashion?

What is the contribution of artificial intelligence to sustainable fashion?

How does 3D printing innovate the fashion industry?

How do autonomous systems streamline the luxury fashion supply chain?

How does robotic process automation contribute to personalized apparel?

Source Links